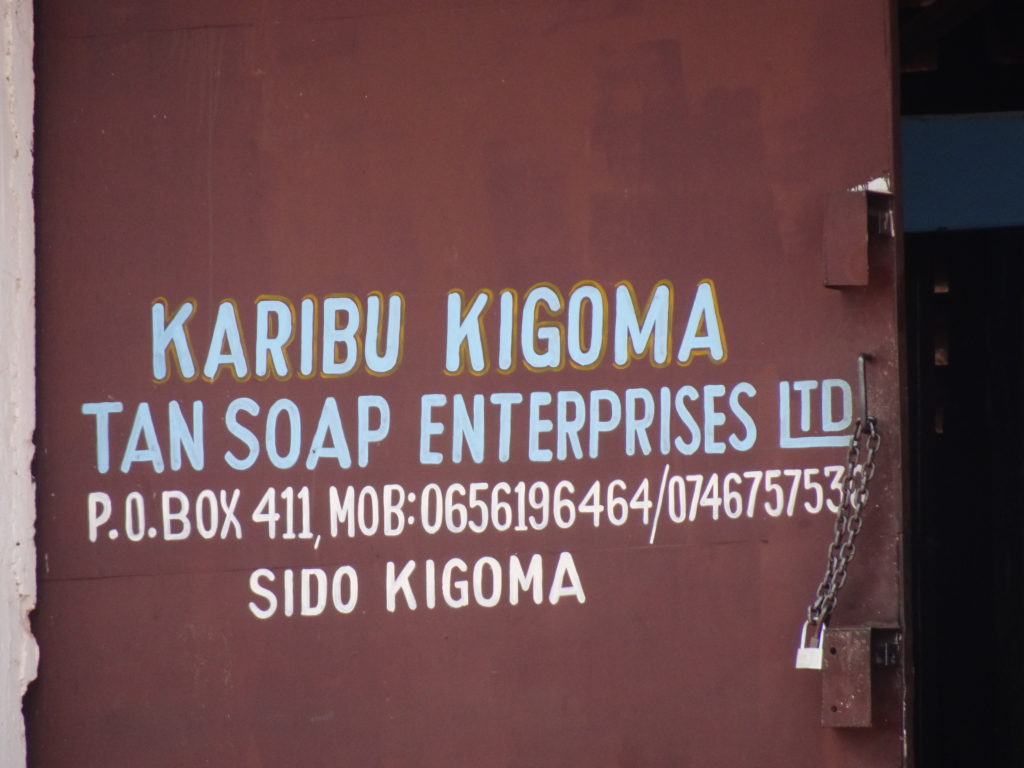

While wandering around Kigoma searching for fabrics, we stumbled into a soap-making “factory” on the outskirts of town. I use the word factory as that’s what they called it, but I’m not sure that’s what we’d consider it in the US as it was all open-air rather than in a building. It was a huge area where a number of folks were making soap, though, so perhaps my definition needs recalibrating?

Anyway, this was one of those spots that you randomly come across while wandering aimlessly in cities around the world. Definitely not the prettiest spots, nor the quietest, and not everyone appreciates them, but I think of these as little gems of experience just ready to be collected! Want to take a look? And a listen? Read on, then.

As you can see, it doesn’t look like much at first. Dust everywhere, rusted tin roofs, open air buildings, LOTS of noise from every direction, and a lot of folks working in very well-worn clothes. Not really enjoyable to see, per se, but fascinating.

Everything starts out with the drying of palm tree seeds.

After drying, they are brought in and put through an incredibly loud machine which crushes them to pull out the palm oil. It must be horrible for the folks working it day in and day out – there’s no hearing protection and it’s got to lead to hearing loss pretty quickly. Take a listen…but I recommend not having your sound turned up too loud!

See? Hoo-boy. Unseen in those clips are the little babies on their mama’s backs and crawling on the floor. Understandably we had a lot of trouble seeing the many little children in the factory. Those piles of brown behind the machine are the crushed husks of the seeds. They get taken out and used for animal meal so nothing gets wasted.

The oil gets poured into barrels and mixed with some caustic soda – that’s essentially what makes it into soap rather than oil.

The mixture is now a milky color which they sometimes add dye to, creating some beautiful color combos.

After mixing in the soda, they then pour the new liquid into wood forms and add the dye before letting it set for a few days. We happened to be there as they were pouring things in! Takes some strong backs to lift those barrels filled with liquid – one of MANY tasks I was glad not to be doing that day!

Time to fill that final mold:

The soap comes out of the molds in blocks that are about 4.5′ x 2′ x 1′. Being a manufactory, these blocks are then sold as is occasionally, but more often they are cut down and sold in much smaller slices. We saw those smaller slices being sold in town where they are much prized by native Tanzanians. I got to use some a few times and they worked just fine indeed.

And there you have it – our visit to the soap-making factory in Kigoma. Not the prettiest or the quietest experience we had in Tanzania, but certainly a memorable one!

I am struck by how hard working and enterprising these people are. Just a fascinating “short story!”

you guys have the best adventures. Love it